The global standard in liquid control.

Hibar Pumps are precision metering pumps trusted in over 50 countries for their precision and reliability.

Make an inquiryHibar Pumps are precision metering pumps trusted in over 50 countries for their precision and reliability.

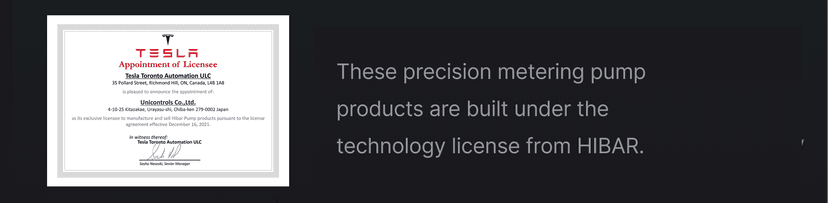

Make an inquiryFor 50 years, Hibar Pumps have been the standard electrolyte injection solution in the battery industry. We also serve food, cosmetics, and pharmaceuticals worldwide. Under a licensing agreement with Tesla Toronto Automation (formerly Hibar Systems), we carry on advanced technology and manufacturing, delivering reliable, high-quality products.

Hibar pumps can be selected to suit the customer's environment based on three selection points: Dispense volume, Viscosity of the liquid, and Drive system.

Minimum:0.02cc Maximum:~2,000cc

1cps~50,000cps

Pneumatic Driven Motor Driven Servo Motor-Driven

Hibar pumps are industrial plunger pumps that demonstrate high performance at sites where accurate dispense is required.

Hibar pumps maintain stable metering performance of ±0.5% or less (nominal value depending on liquid and filling volume) even when changes in fluid temperature or viscosity occur. It is particularly capable in situations that require high accuracy.

The use of a shut-off nozzle allows "stringy" or slurry-like liquids to be dispensed without dripping.

The lineup includes pharma pumps that do not use seals at all in sliding parts. Prevents foreign matter and impurities from entering the pump.The lineup includes pharma pumps that do not use seals at all in sliding parts. Prevents foreign matter and impurities from entering the pump.

Each block of the Hibar pump is divided into two parts: the part that comes in contact with the liquid (wetted part) and the part that drives the plunger (drive part). For daily cleaning, only the wetted part can be disassembled, and parts replacement and cleaning can be done with simple operations.

Using pneumatic drive, it can be used in explosion-proof areas and wet area.

In the case of pneumatic drive, the dispense volume and speed can be easily and freely adjusted by means of a micrometer or needle valve. In the case of motor drive, the dispense volume and speed can be controlled by setting numerical values from a PC or other external signal.

Hibar pumps are chosen for a wide range of applications, including the automotive industry, chemical plants, and general manufacturing processes.

Cosmetics and toiletries

Hibar pump Model:2BC12

In small-volume, high-mix production

Filling the containers with a fixed volume of fragrance oil

Although we had line equipment for high-volume filling, it was having difficulty coordinating production due to the increasing number of small-volume, high-mix projects.

With the introduction of the Hibar pumps, we are now able to handle small-lot, multi-variety lot filling operations while saving space, thereby expanding the range of products that can be supplied.

Also, the easy filling volume adjustment of the Hibar pumps leads to increased work efficiency.

Since the filling operation can be performed at the touch of a button, it is very easy to operate, regardless of the operator's experience level, and operating errors have been greatly reduced.

We are very satisfied with the safety measures taken.

A. Of course, motor-driven pumps can be used, but even with pneumatic-driven pumps, the amount can be adjusted with a micrometer and the speed can be adjusted with the speed adjustment knob.

Contact us to speak with a sales representative or expert to find out how Hibar pumps can help you meet your productivity and cost reduction challenges.

Since its establishment in 1976, Unicontrols has always been committed to this mission and has been meeting all the needs of our customers.

Unicontrols, which has honed its technology and expertise through a lifetime of liquid control, provides total support, including design, production, and after-sales follow-up, for the introduction of optimal systems to solve customers' problems.

We provide up-to-date information, focusing on behind-the-scenes production, products, and trade show information. Please follow us.